The Facts About Paint Protection Film

Paint protection film is a modern marvel. It’s a thin but exceptionally durable polymer or polyurethane film that is the ultimate layer of protection. Not only does it keep your ride’s clear coat protected against chemicals, UV exposure, acid rain and road debris, but if the vehicle’s paint is impacted by road debris, it can save you thousands of dollars in autobody repair.

There is a lot of information on the interwebs about paint protection film. Some of it is accurate, and others are pure, 100 percent, grade A BS. Search up ceramic coating and you’ll get similar misleading information. So, let’s explore the truth about paint protection film.

In this article – we’ll weed through the myths, rumors, and flat our false information out there, to provide a definitive guide about paint protection film. Does it really protect from light scratches? Can PPF actually self-heal?

Want to get a free estimate for paint protection film? Get Your Free Quote NOW!

We’ll also introduce you to Kavaca instant healing paint protection film – the most advanced PPF on the market today. Additionally, we’ll explain why it makes sense to apply a professional grade ceramic coat on top of that PPF – to create the Ultimate Shield of protection. If you’d like to compare PPF vs ceramic coating, we’ve got a great article you can review after reading this one.

What is Paint Protection Film?

In order to fully appreciate the power of paint protection film, it’s important to explore it’s history. Like many of today’s modern achievements, PPF was developed to solve a problem. During the Vietnam War, the United States Department of Defense was having trouble with rotor blades on several of their helicopters being damaged by shrapnel, trees, and other debris.

The folks at 3M were tasked to create a protective layer that was lightweight, yet incredibly strong. The solution was called helicopter tape or a custom urethane film that was designed for function – not style.

Today’s PPF is far cry from 3M’s helicopter tape. It’s thermoplastic urethane that is transparent, can be colored, even custom textured to enhance gloss or matte paint jobs. It is a clear paint protection film that can be purchased in different grades, thickness, and is applied by highly trained professionals with precision accuracy.

In fact, the present-day paint protection film produces multiple benefits including:

- Resistant to acidic corrosion and contaminants (like bug guts and bird droppings)

- Protects a painted surface against acid rain, mineral deposits, soft and hard water spots

- Reduces oxidation on factory paint caused by UV light

- Blocks small rocks, gravel, tree branches and other hard objects from hitting paint surface

- A protective film can heal itself if it’s scratched or struck

- Lasts for up to 10+ years

What are the Types of Paint Protection Film?

There are a lot of coating for cars on the market today. But paint protection film is arguably the best and most-effective solution. The 3M Corporation is the Godfather of PPF. As explained above, its primary application was to apply a tint to protect lightning-fast spinning helicopter rotor blades from being damaged. Today, more than a dozen different types, brand names, and designs are offered to car enthusiasts.

You’ve probably heard of some of the leading brands including our own Kavaca, 3M Paint Protection Film Pro Series, Llumar, Suntek, and Xpel film. However, it’s commonly misunderstood that the brand of PPF is associated with the type of product.

While sometimes this is the case, the brand is not always related to the material or its proprietary properties. This is one of the myths or misleading PPF truths that can confuse car owners. Some are applied as full wraps while others are partial hood. There are several that offer limited warranties and some that can back up their product with a 10-year warranty.

Let’s provide some clarity here.

What is Clear Bra?

Arguably the most popular ‘name’ in the paint protection films market is clear bra. This is a dual-purpose term – kind of like calling a soda pop a “Coke” – or sealable plastic bags “Zip-Lock”. Clear Bra is a brand name for a specific type of protective film. But, it’s also a specific brand as well.

It’s applied to the front end of the vehicle, covering the front bumper, car’s paint, grille, headlights, splitter, and even the front portion of the hood and front fenders. The term “bra” is used to describe the location of the application.

What is the Difference Between Vinyl and PPF?

If you’ve read previous articles offering PPF buying tips, you might have read about vinyl or car wraps. Another confusion that occurs is understanding the difference between paint protection film or PPF and vinyl – or also called a vinyl wrap.

Essentially, PPF is a thicker, stronger, yet lightweight material. It provides stain resistance, protection from stone chips, light scratches, bug splatter, swirl marks, and other paint damage.

Vinyl is heavier, thinner, and typically colored. It can also be decorated with graphics. Here is a practical example. This image below a great example of a vinyl wrap. It’s a branded vinyl that is applied to the original paint of a specific vehicle. It replicates a “sticker” – but also provides protection for the paint underneath. The car is David Douthit’s Quartermaster Nostalgia Jet Funny Car. The entire car is painted, but the bottom of the car is vinyl wrapped. What’s really cool is that the words on the car light-up when the car is on.

Explaining the Science Behind Paint Protection Film

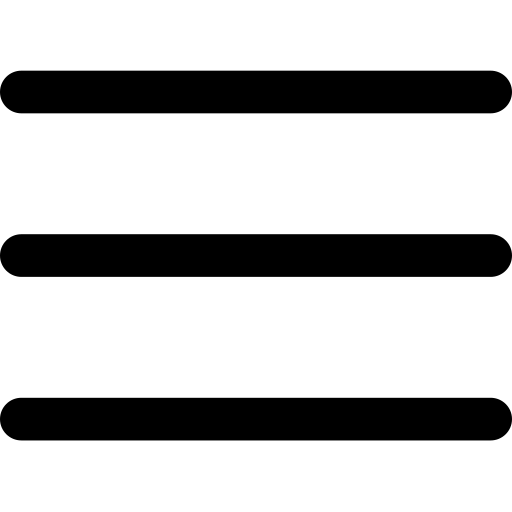

OK – let’s get technical. Most automotive paint protection film are based on the same physical construction. It’s broken down into four individual layers:

Acrylic Adhesive: The next layer up is the acrylic adhesive. It’ is a bit thinner – measuring 1.6 mils (or 0.040mm). This provides the durability of adhesion.

Polyurethane: The bulk of PPF is polyurethane. This provides the depth and strength of the paint protection film and measures 6.0 mils (0.152mm).

Clearcoat: The final layer is clearcoat. It measures 0.5 mils (0.0132mm) and acts as the surface layer of the PPF. It is also what helps a ceramic coating like Ceramic Pro to bond on top of the PPF. Some self-healing PPF’s are topped with an elastomeric polymer that helps the material maintain its natural shape once it has been stretched or applied.

How Can a PPF Self Heal?

Let’s be 100% clear – not all products in the paint protection film market have self-healing properties. The ones that possess this attribute are comprised of Elastomeric polymers. This introduces today’s word of the day – “Elastomeric”. So, what does this mean?

Well, the word itself is an adjective which describes the nature or action of materials that are elastomers. Elastomers are cross-linked polymers that are loosely attached. It’s a synthetic or natural rubber that can return to its natural state when the source of the damage is removed.

When a high-quality paint protection film is comprised of this material, the application of heat (either natural by the sun or a heat gun) will repair damage like scratches or even minor tears caused by an impact from a rock. If the PPF is repaired in this method, the term ‘self-healing’ is a bit inaccurate, as it requires an outside physical action.

Is There a True Self-Healing PPF?

There are a lot of people that flat out wonder how does PPF work. Well, as we explained above, the science infused in these advanced materials helps to block common road debris from damaging the vehicle’s surface. If it’s hit hard enough, the PPF may in fact scratch. This is where the self-healing properties of paint protection film comes into practical application.

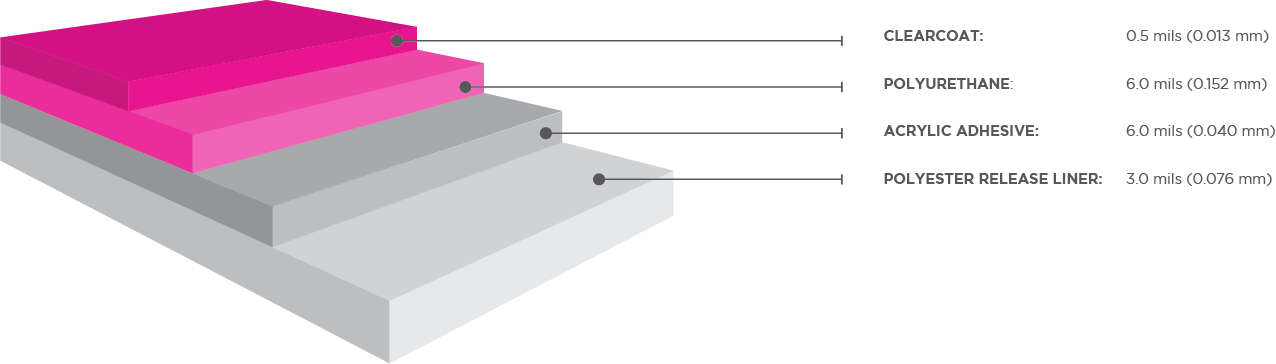

However, if a product is truly self-healing, it should possess the technology and ability to fix itself without an outside source. A new, revolutionary paint protection film called Kavaca – by Ceramic Pro is a genuine Instant Healing PPF.

Watch the video below to learn how Kavaca works.

How is Paint Protection Film Installed?

Like any other paint protection solution, correct prep work, installation, and aftercare is crucial to the success or failure of a PPF. Ceramic Pro is known for their ceramic coating products, but they also manufacturer a superior clear bra material that is called Kavaca. Installing a clear bra pattern or a full coverage that

The installation process is unique for each manufacturer, but the process follows these general steps:

Step One – Prep Work for Paint Protection Film Installation

For a PPF to protect, it’s got to be bonded to a surface. This becomes possible when that surface is clean, free of debris, and any damage. However, since a paint protection film is transparent, the condition of the paint or surface underneath makes a huge difference in the brilliance of the finished product.

What is a Decontamination Car Wash? A decontaminating car wash is typically the first step of PPF prep. It involves the use of a wax-stripping car shampoo that acts as a detergent, which breaks down the oils in wax, factory paint sealant, and allows them to be washed away.

If you have a ceramic coating applied to your entire vehicle, the professional detailer that installs clear bra film will simply complete a maintenance car wash. If there are minor scratches due to rock chips – or if you have an older paint job, the auto detailing company might want to repair those issues in the next step.

What is Paint Correction? Once the surface has been cleaned and stripped of initial debris, the installer will inspect the condition of the paint. If it is faded, aged, has spider-webbing or swirl marks, or shows signs of damage, the installer will recommend paint correction to the client.

This involves polishing or using a cutting compound to remove minor scratches or imperfections in the paint. The final result is a perfectly smooth surface that allows the PPF to bond but also allows the brilliance of the finish to shine.

Final Wipe Panel Wipe Down: Using a proprietary blend of chemical agents, the authorized and certified PPF installer will remove any contaminants or excess polishes or oils on the surface.

Step Two – Pre-Cutting the Material

There are two types of methods for applying the PPF. Most professional installers of PPF use a plotter or a machine that pre-cuts the material in smaller, custom-fit sections – like a fender or door edges.

This helps to reduce waste, save the client and installer money, and of course – resources. It also is crucial to expediting the PPF installation and making it fit better in smaller sections like door jams, headlights, and grilles.

The second method is using bulk film. It’s basically used when an installer does not have a plotter – and tends to result in excess material, more time, and less precision or accuracy of the installation.

When used by an experienced installer, these problems can be mitigated. In fact, some are so good that they can hand-cut to fit rocker panels, side mirrors, the hood, deck lid, spoilers, and more.

Step Three – Fitting

To ensure accuracy, the installer will pre-fit the car protection film. The paint protection film market is filled with multiple brands and types of installation types – like a clear bra that only goes on the front of the vehicle. Fitting the clear bra to the paintwork is a tedious and precision process that verifies that the material will fit each section and connect or blend with each other with reduced gaps.

While this does add some additional time to the complete process, it’s worth it in the end – as it will protect the paintwork and other areas of the vehicle against rock chips or a light scratch, which can be fixed easily with self healing PPF.

Step Four – Spraying the Fitting Solution

The activator which permits the clear bra or PPF to bond to the surface is called a fitting solution. When sprayed to the painted surface and on top of the PPF, it activates the adhesive – which is a glue basically and bonds tightly to the surface.

Again, each brand of PPF has recommended fitting solution properties, some can range from distilled water to chemically-activated agents. This helps it bond to a car’s paintwork, helping to block UV rays, oxidation, corrosion, and eventually the development of rust.

Step Five – Application and Final Fit

This is the step that makes the magic occur. The experienced PPF installer will carefully glide the PPF into perfect fit. It’s a process of fitting, spraying solution, moving around, squeegee of bubbles, and more. When it’s in the exact position, the installer will use a squeegee to remove creases or bubbles from the PPF. Once the PPF clear bra has bonded to the paint surface, it provides exceptional sealant or surface protection on the car’s exterior – especially against a normal scratch, bird dropping, a rock chip

Step Six – Drying

The final step of the clear bra or PPF installation is drying. This can be done a few different ways – either by time or using a specific drying procedure. Most professional PPF’s are heat-activated by use of a heat gun or even placed into a heat chamber. The process essentially activates the ‘glue’ and restricts the material to create an incredibly tight fit.

How Long Does Paint Protection Film Last?

A professionally prepped and applied paint protection film has an expected longevity of five to 10 years. However, like any other paint protection solution, the durability of the PPF is impacted by several variables.

The Prep Work

Like we stated above, the condition of the surface prior to applying the PPF is a major factor that impacts longevity of automobile protection. If the surface is clean, free of scratches, and any contaminants, the adhesive will bond better and ensure a tighter fit.

The Application

Having a certified paint protection film installer complete the entire process is another surefire way to extend the lifespan of your PPF. The material and supplies they use is just as crucial.

Most PPF brands, like Ceramic Pro PPF Kavaca partner with the best professional detailers and installers, have advanced training and certification process, to ensure their clients receive the best possible service. Working with the right PPF dealer will reduce air bubbles in the finished product, which makes the PPF look seamless.

Inferior top coat materials are common in cheap products, which leads to yellowing or potential for a stain to occur. It also provides reduced protection against bug acids.

Environmental Factors

While a PPF is intended to protect the surface from exposure to UV light, acid rain, bird droppings and other environmental factors, too much can have negative consequences.

To reduce this potential, applying a professional-grade nano ceramic coating on top of the PPF can provide an additional layer of protection – extending the life span to the lifetime of the vehicle in some cases.

What are the Pros and Cons of Paint Protection Film?

We’re not here to blow smoke – but to provide facts. And the fact remains that paint protection film is not for everyone. While it’s a great way to reduce scratching, rock chips, and other surface damage, it comes with some pros and cons to consider.

Pros of Paint Protection Film

- Strongest material to protect against rock chips and paint damage

- Incredible healing properties – like Wolverine – if you want Deadpool healing, an Instant Healing PPF like Kavaca is perfect

- Prevents paint scratching, marring, or swirl marks

- Longest lasting paint protection solution on the market – up to 10 years or more when combined with a professional-grade nano coating

- Better engineering and technology than in years past – no more yellowing or reduced hydrophobic properties

Cons of Paint Protection Film

- Many grades of PPF. Not all products or brands are same – so do your research to choose the best solution for your application.

- Difference in Self Healing Property: There are some PPF’s that offer the ultimate paint protection film properties – by instantly healing scratches. But most are ‘self-healing’ that require some heat or physical repair techniques to remove the surface scratches.

- Not a DIY solution. A paint protection film is a professional-grade clear film product that should be applied by experts. While there are DIY clear bra products, results simply don’t match professional-grade PPF

- It’s an investment. There is no way to spin this – PPF is not cheap. It’s an investment in the quality and condition of your vehicle. It’s always best to work with a certified PPF dealership or authorized detailer.

Expanding the Life and Effectiveness of PPF

We mentioned this briefly above, but the best way to protect and enhance your paint protection film is to have a professional-grade nano-ceramic coating applied on top.

A Ceramic Pro solution is comprised of silicon dioxide or SiO2, Titanium Dioxide or TiO2, and a group of proprietary polymers and ingredients that form an exceptionally strong layer of protection on top of the PPF.

It’s basically a liquid form of quartz or glass, that penetrates the microscopic valley’s found in the PPF top layer, then hardens to create an ultra-smooth and flat surface. A ceramic coating can protect your headlight covers, glass, carbon fiber, and vinyl wrap. When it’s applied, it leaves a hydrophobic surface, which makes water, dust, debris, tree sap, bug splatters, and more less likely to stick. This is known as producing a super hydrophobic effect.

Benefits of Applying Ceramic Coating on PPF

When you apply a nano ceramic coating that is engineered to bond with the exact material of the PPF you choose, it can provide multiple benefits.

Increased Depth and Shine: When a nano ceramic coating cures, they transform into a thin layer of glass that is as strong as quartz. This amplifies the brilliance of paint found under the PPF, which increases the depth of the paint below – whether it’s gloss or matte finish.

Improves Hydrophobic Properties: Hydrophobic is a fancy term to describe a surface ability to repel water. However, beyond producing optically cool water shedding and beading, it also helps to reduce the potential of dirt, pollen, and other contaminants from sticking. For example, if you’re an enemy of pigeons – and they drop a deuce on your ride, a ceramic coated PPF makes it simple to remove their waste.

Extended Lifespan: The strength and durability of a professional-grade Ceramic Pro coating is far superior to even the best DIY nano coating. Professional grade coatings are comprised of more than 90 percent SiO2 – which is about 10% more than the leading self-applied coating. This results in a stronger and longer-lasting coating and a PPF that still maintains self-healing properties.

What’s the Verdict on PPF?

Just like there are different grades of car wax, ceramic coatings, and paint sealants, there are just as many different paint protection film products on the market. If you’re considering the investment into a high-quality PPF, consider the following.

- Complete Due Diligence: Before spending money on any major purchase, make sure to research the product you’re thinking about buying. This is especially true with paint protection film and those who apply it.

- Does the PPF Work as Advertised: As an industry, PPF is less susceptible to gimmicks and marketing buzz-terms. However, it’s important to verify through third-party reviews, and looking into the technology infused in PPF to ensure it does what the manufacturer claims.

- Is it a True Instant Healing PPF: Arguably the best attribute of paint protection film is it’s ability to heal when it is lightly scratched or damaged. If you need to take your ride to the installer each time you have a minor scratch, this is going to add time – and often more cost to your overall expense.

What is the Best PPF in 2020?

By investing in an Instant Healing PPF like Ceramic Pro’s Kavaca, you’ll receive an honest and genuine instant healing solution. It’s the only PPF on the market today infused with nano-technology that does not require professional help to self-heal. It’s truly the best PPF, offers you superior protection, and can hold up for 10 years or longer.

KEY PROPERTIES:

Kavaca Instant Healing Film

Your ride is your passion. If you’re looking for the best paint protection film on the market today, click the button below to receive a customized free estimate.