If you are considering applying a paint coating to your car, the most popular paint coating used by vehicle owners is ceramic coating, which is a solid option for sprucing up the look and integrity of your car’s coat similar to self-cleaning or paint correction.

After decades of auto enthusiasts, professionals, and car owners experimenting with products to add shine that are long-lasting and easy to apply, the top picks on the market today boil down to ceramic coating, wax, and sealant.

There are several products in the coatings industry – from powder coating pigment-based solutions, to industrial coatings for steel, aluminum, and iron. In the automotive consumer segment, the best protective coating will be one that is applied by a professional detailer, offers years of protection, reduces corrosion to block the formation of rust, enhances the vehicle color, superior durability, and heat resistance to block UV rays.

There are multiple specialty coatings on the market today – which makes finding the best coating material difficult and time consuming. To avoid the frustration, we’ve outlined this article to explain the different options available to you.

How Does a Paint Coating Work?

Paint coatings bond directly to your vehicle’s paintwork, cross-linking and adhering to your paint, unlike waxes and sealants which sit on top of your car’s paint. However, there are multiple grades of consumer and industrial paint coatings. Some (polymer-based) bond on top of the substrate, while others (Quartz-based using nanotechnology) penetrate the imperfections on porous materials, fill those gaps, harden, and become “one with the substance”.

Paint coating is most often wiped straight onto a car’s paint and then the solvent within the coating is left to evaporate. You then wipe off the excess as needed.

This new thin layer cures directly to the paint of your car, which generates a hard shell of protection. This new semi-permanent layer provides UV resistance, water resistance, chemical resistance, makes your car look glossier, and protects your car against light scratches.

How are Ceramic Car Coatings Made?

Ceramic car coatings are made from nano particles of resin or quartz which are combined with a solvent which when spread across your car’s paint evaporate, leaving behind a smooth finish.

These coatings are most often applied to a foam applicator using a syringe or spray and then get wiped across the surface of your car.

Wax vs Sealant vs Ceramic Coating

Between wax, sealant, and ceramic coating, wax lasts the least amount of time. However, wax is also more forgiving regarding surface preparation and takes less time to apply. If you use wax, you can expect your car’s paint to have more of a warm glossy look and be softer than usual.

Sealants, on the other hand, last much longer than waxes – usually several months. In some cases, the application and surface preparation process can be easier as well. Unlike some waxes which are all-natural, sealants are made of synthetic chemicals and give your car’s paint a wet, glossy look or sheen.

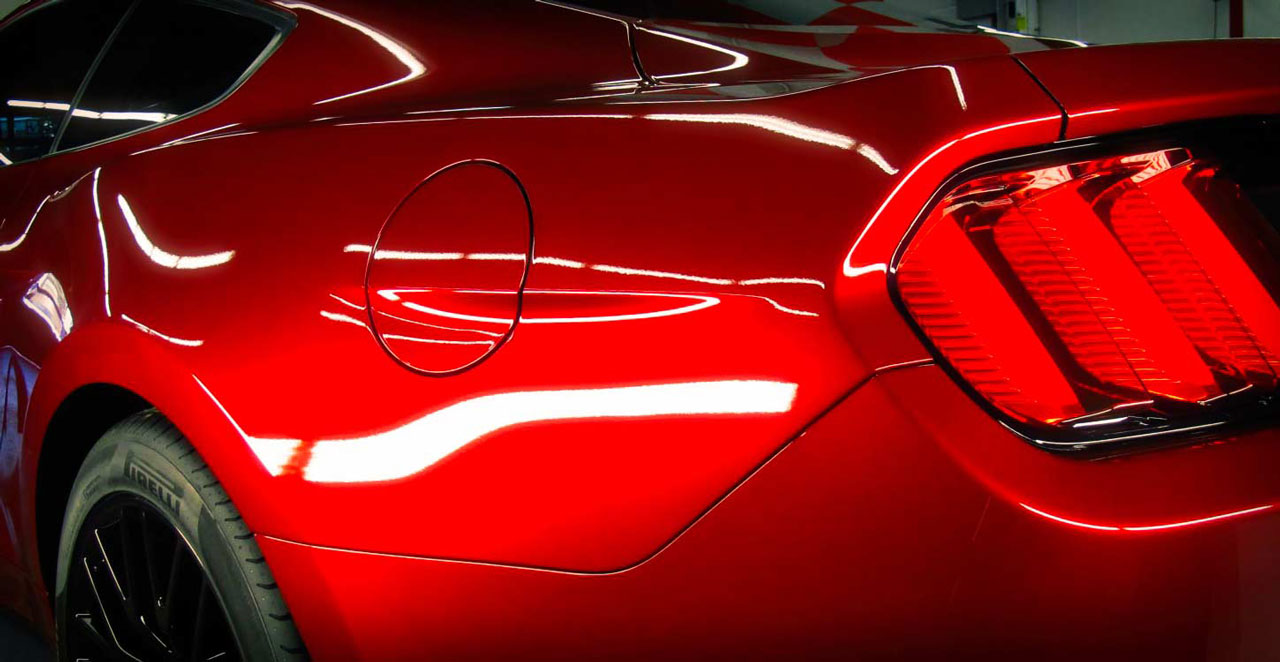

Last but not least, paint coatings are not particularly difficult to apply but are the least forgiving. They do, however, last the longest by far. The key to ensuring paint coating lasts as long as possible is to prepare the surface of your car sufficiently. After applying a paint coating to your car, you can expect a very shiny, glossy look – like candy coating.

While all three are great options, my personal favorite is paint coating, as not needing to do anything other than washing my car to keep the paint looking clean and shiny for over a year is super convenient.

Benefits of Paint Coating for Cars

There are several benefits to using paint coating that is far superior to traditional wax or sealants. Firstly, paint coating will protect your car’s paint. Some of them like natural carnauba wax will hold up for a few months, while other lab-created solutions like a nano ceramic coating can provide a lifetime of protection.

While it varies from brand to brand, most professional grade paint coatings can last from 3 to 7 years. Many of them come with warranties and require an annual inspection to keep the paint coating in great shape and the vehicle protected.

Paint coatings have several nice properties as well. Mainly they are hydrophobic – which means they bead and shed water, dirt, dust, and light debris. This keeps the vehicle cleaner for longer periods of time.

A strong paint coating like a 9H nano ceramic coating forms a glass coating shield of protection that elevates the vehicle’s paint surface to produce chemical resistance, UV resistant, and act as a protective layer against water etching, bird droppings, bugs, and light scratches.

Also, ceramic coatings enhance the visual appeal of your car’s paint by giving it a sharp, clean, candy-coating rich appearance rather than the standard soft, warm glossy appearance from traditional waxes. This is especially beneficial to owners of cars, trucks, and SUVs with a matte finish – as the coating does not create gloss – but a deeper appearance. It keeps the matte finish – without enhancing gloss.

Drawbacks of Paint Coating for Cars

The two biggest drawbacks to applying a high performance paint coating to your car are the prep work needed and the cost. Also, if you enjoy those once every few months weekend detailing jobs, then the fact that the coating lasts longer than waxes/sealants could be a drawback as well.

Surface preparation is crucial to the application of paint coating and must be done right. This process entails polishing or compounding and wiping down with solvent to remove waxes or polishing oils. If you don’t want to go through this process, then it might be best to go with waxes or sealants. However, it’s just a crucial to prep the surface to ensure a solid bond, and reduce the potential of paint corrosion.

What Types of Paint Coatings Exist?

There are many types of paint coatings: nano, epoxy, polymer, ceramic, quartz, silicon, glass, and others. Within the different classifications are unique application types. Some coatings are applied via spray, others by hand using a microfiber applicator sponge and cloth and buffed off with a microfiber towel. Generally, the two, primary type of paint coatings – often classified or advertised as ‘ceramic’ are either polymer or quartz based.

What is a Polymer-Based Coating?

You have likely heard the term polymer associated with many different products. That’s due to the fact that this substance or molecules are highly diverse. Essentially, a polymer is a molecule that is formed by combining other smaller molecules that are known as monomers. In fact, the word itself is translated as “many units”.

There are some polymers that are natural and other that are synthetic. In the paint protection world, the polymers are known as epoxy, which cross-links with the vehicle’s clear coat and creates a semi-permanent bond.

What is a Quartz or Glass Coating?

Quartz coatings are formulated by combining different dioxides – of silica and titanium (with regards to nano ceramic coatings). Most quartz or glass coatings utilize nanotechnology to penetrate those microscopic imperfections you find in all porous surfaces. It then bonds directly in the surface, which creates a stronger adhesion, producing better protection and longer lasting results.

It turns out that for most modern coatings, the name is nowhere near as important as how easy it is to apply or how long it is warrantied for. Cheaper DIY paint coatings have lower lifespans and premium or professionally installed coatings will last much longer and include a warranty. Many less expensive DIY coatings are starting to improve, but there are multiple variables that impact the overall quality of the installation and the end results.

How Are Paint Coatings Applied?

The process of applying paint coatings is straight forward – the paint coating is placed onto an applicator from a syringe or spray and wiped evenly across the car’s surface. Ceramic coating application takes some time, as the solvents within the coating must evaporate before you can wipe off the excess coating. This is known as ‘flashing’.

The type of carrier solvents and the percentage of them will serve two purposes. First, it allows the coating to layer on top of each application, and second, it determines the time or window of applying and then removing. Generally, DIY coatings are formulated with low carrier solvents, which means they can’t build layers, but offers an easier application.

Professional coatings like Ceramic Pro 9H are formulated with complex carrier solvents – which allows it to build multiple layers. However, application is tricky and is only completed by professionally trained technicians in a controlled environment.

Whichever coating you go with, it is always best to follow the specific application instructions that come with it. Generally, however, the process is as follows:

- Prepare the car’s surface by polishing imperfections and/or waxes

- Wipe down the car with a wax/grease removing solvent

- Apply a small amount of ceramic coating to an applicator and wipe it across a section of your car’s surface no bigger than 2′ x 2′. In this small section, wipe back and forth and up and down until the coating is evenly distributed.

- Wait for the solvent to evaporate if needed, also known as the “flash off” period

- Wipe off excess coating with a soft, clean microfiber towel until there are no more streaks (high spots) or haziness

Tips for Applying Ceramic Paint Coatings

- If you are using spray coating, then be careful with spraying it onto windows and/or adjacent panels. If you do overspray, be sure to wipe it off and not let it dry.

- If you are using spray coating, make sure to close the nozzle after you are done to prevent it from drying shut.

- A general rule of thumb is that less is more. Wiping on too much coating at once will generate more high spots which will be harder to wipe away.

- It is preferable to apply coating somewhere where there is ventilation, or you can wear a mask, since these coatings often have strong fumes.

- It is also a good idea to wrap a layer of suede around your foam applicator. This will help the coating apply even easier and prevent the coating from soaking into the applicator itself, which means it will last longer.

If your car has new paint, then it is not recommended to apply ceramic paint coating. New paint has gases and solvents which have still not evaporated, which can cause damage when mixed with the solvents in paint coating. Whoever painted your car should be able to recommend how long you must wait until you can apply paint coating to the new paint.

What’s the Alternative to DIY Paint Coatings?

There are multiple variables that impact the quality of a DIY paint coating installation. More often than not, the installation will create problems, such as high-spots – which can only be removed by using harsh chemicals or via paint correction. DIY coatings have a very short life-expectancy vs a professional coating, provide less protection, and are often over-hyped by the companies selling them.

The alternative is Ceramic Pro 9H. The coatings are sold in warranty package levels, allowing you to pick one that fits your needs best. If you’re going to trade in your car every few years, the Bronze package offering two years of warranty protection is perfect. For those with collectable vehicles or commercial trucks, RV’s, and other longer-lasting vehicles, a Silver or Gold package is better suited.

Regardless of which one you need, want, or desire, our team of over 3,500 professional auto salons across North America are here to help. If you’d like to request a free quote or estimate for Ceramic Pro 9H paint coatings, click the button below.