Microfiber is an amazing material. Depending on who you ask, it was either designed or invented in Japan, Korea, Germany, and between the early 1970s and 1980 something. In fact, it seems there is more misleading information and facts about microfiber towels than truth. This is what we will endeavor to change today.

In the information below, we are going to breakdown the truth about microfiber cleaning cloth used in auto detailing. We will explain what makes a microfiber towel good, the different elements infused in microfiber, the ratings, a which type of microfiber towel is best for a specific detailing application.

But first, take some time to review this awesome video by Ceramic Pro’s Adam Cote – as he introduces quality microfiber towels for common car detailing jobs.

How is Microfiber Made and Rated?

One thing all detailers can agree – using paper towels is simply no longer an option. Using microfiber cloths and materials is the ONLY way to go. But what exactly is microfiber and why is it different than regular towels and cloths?

Microfiber itself is a continuous filament fiber, which essentially means it is comprised of two different materials – polyamide and polyester. Polyamide is a byproduct of nylon and is the material within microfiber towels that helps with the absorption of liquids. Polyester fibers improve the softness and the anti-scratch properties these towels are known to produce. It’s just much softer than a traditional cleaning cloth.

At the factory, microfiber manufacturers use specialized equipment and specific grades of raw materials to assemble and end use product. However, when you break it down simply, there are two important criteria that will determine the applications for using microfiber towels in the detailing process.

What is a Microfiber Split?

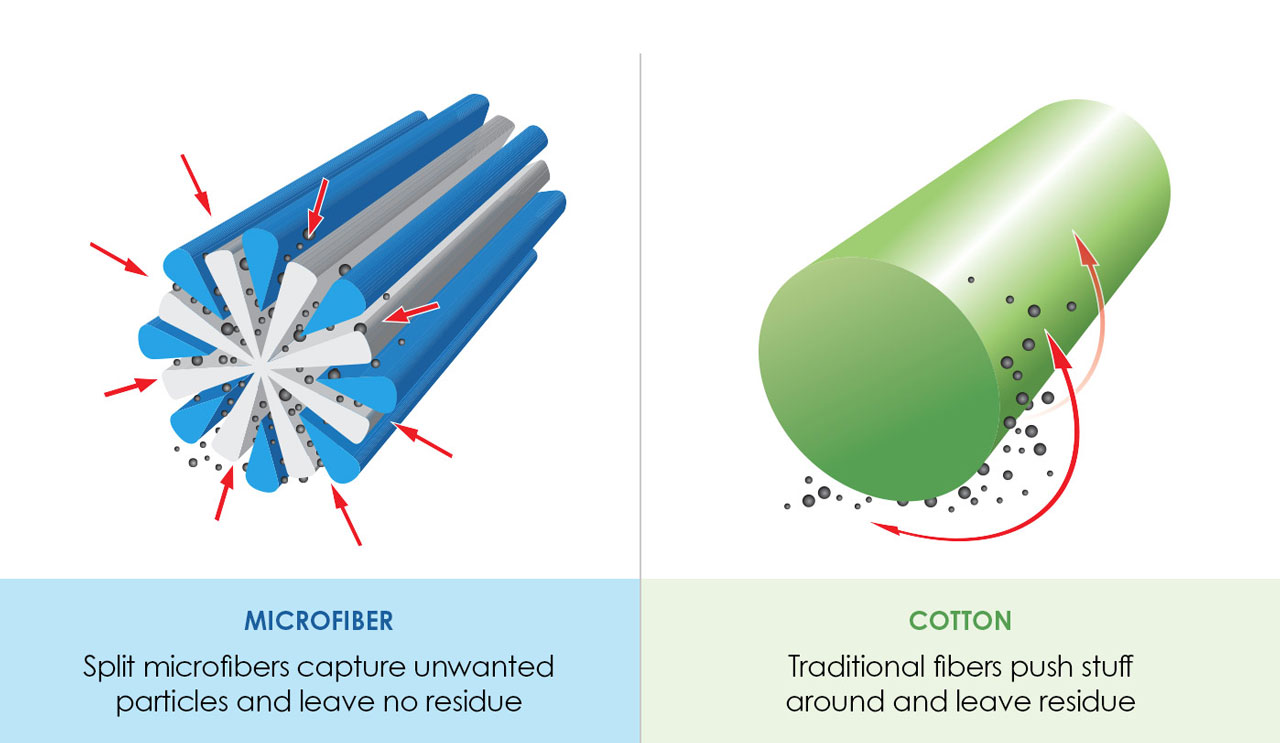

By definition, a split is a combination of multiple individual elements. With microfiber, the split refers to the pattern in which the microfiber materials are sewn or assembled for lack of a better term. Polyamide and polyester are combined and stitched in a pie shaped pattern, which is commonly known as the microfiber split. The size of each pattern or specifically the depth of material will impact the product pile, strength, and weight.

The microfiber split is important due to the differences in surface tension of the two materials. When the split is created, it establishes multiple grooves within the fabric that helps to reduce scratching while it is collecting materials on a surface. it is this quality that determines the softness or application of a microfiber cloth.

For example, a microfiber towel with an aggressive split is best used for sensitive materials that are prone to scratch. Microfiber with a split that is less aggressive is optimal for picking up liquid’s or absorption.

What is the Microfiber Ratio?

Arguably the most important element with regards to rating the quality of microfiber is the ratio of materials. We mentioned it earlier, but it is important to drive this message home – microfiber towels in cloths are comprised of polyester and polyimide. Some microfiber towels will include a velvet or silk liner installed on the edges to help reduce scratching – at least that is the theory anyways.

The ratio of the two materials tends to impact the strength and absorption of the towel. Two general ratios exist for most microfiber towels used in detailing – 80/20 and 70/30 – with the larger number represented by the percentage of polyester – and the smaller being polyamide.

It was assumed by many so-called detailing experts that the higher percentage of polyamide (or a 70/30 ratio) had a direct correlation to the softness or overall quality of the towel. However, as manufacturing technologies and techniques have improved, and the overall quality of each raw ingredient has likewise been enhanced – the gap of quality between the two ratios has narrowed.

What Impact Does Country of Origin Have on Microfiber Towels?

Another outdated myth about microfiber towels has to do with the country of origin – specifically where are they made and where are the raw materials sourced? With microfiber, there are two main combatants in the manufacturing world – China and South Korea.

Korean microfiber tends to be more consistent, softer, and more absorbent. It is common for many Korean microfiber blends to have a ratio of 70/30 with higher GSM or grams per square meter ratings (we will explain that below).

Initially the difference in product quality mainly had to do with the integrity of the raw materials and precision tolerances or quality controls with South Korean manufacturers. In the past five years, several Chinese manufacturers a microfiber towels have stepped up their quality standards and, in many cases, are using superior quality raw ingredients.

So – as of 2020, the country of origin is not as big of a deal with automotive detailing microfiber than in years past. But you will notice a higher cost of goods with many Korean manufacturers versus Chinese microfiber providers – but the gap in price is likewise narrowing.

What is GSM with Microfiber Towels?

There are some professional detailers or certified YouTube experts who swear by GSM to determine the quality of microfiber. GSM stands for grams per square meter or the weight of the filaments within the microfiber towel.

This number is calculated based on weighing a 9000-meter-long strand of the combined microfiber blend. But here is something that most people have no clue about – a single strand or filament of microfiber is 1% as thick as human hair. It takes 200,000 microfiber filaments to complete one square inch of finished microfiber material.

The grams per square meter of weight is based off something microscopic that you cannot see well with the human eye. However, the GSM is important when it comes to determining the quality or longevity of microfiber. Higher GSM towels tend to hold up longer when washing microfiber.

For example, if you were going to compare two identical microfiber towels, with the same split, ratio, and country of origin or manufacturer – the one with the higher GSM rating should hold up longer than the lower rated item.

It is important to understand that GSM should never be the only criteria you use to determine whether a microfiber towel is the right one to use for a specific detailing job.

What are the Types of Microfiber Towels?

Now that we have broken down the basics above, let us explore what type of towels are used commonly in automotive detailing.

All-Purpose Microfiber Towels

Every detailer knows the value of having a large inventory of clean multiple purpose microfiber towels in their shop. This towel is essentially the workhorse that does all the dirty work, such as cleaning wheels, suspension parts, door jams, and under the hood. most of these towels feature an 80/20 blend of polyester and polyamide, a GSM rating around 300, and measure 16 x 16-inches generally.

All-purpose MF towels have a ‘hooked’ design – meaning it is designed to allow the towel to spread liquids evenly. This makes them great for degreasers, spray wax, waterless washing, or even boost sprays. It is not great for drying – but you can use it on less detailed surfaces like those mentioned above.

Glass Microfiber Towel

The glass microfiber towel is like all-purpose with a major difference – lint free and a different weave or split. When you use microfiber towels for cleaning glass, it is important to have one that is going to spread the glass cleaner evenly and have absorption qualities that were reduced streaking.

A glass microfiber is going to have a smaller and tighter weave and a nap (which is the depth of the weave). You will notice that a glass microfiber towel simply looks smoother or has a less aggressive surface than the average all-purpose towel.

The GSM and construction percentage or ratio is typically the same as all-purpose towels, so it is important to visually inspect the glass microfiber.

Buffing Microfiber Towels

Another important task with automotive detailing is buffing, specifically removing the residue of liquids that have been applied without scratching the delicate surface. This is done by using an incredibly soft buffing towel. The best ones usually feature a 70/30 ratio, have a high GSM, and physically look very ‘fluffy’.

There are two general types of buffing towels – those with a tight and short weave (which are good for waxes) and the plush and soft construction type – which is best for liquid sprays. The key is to find a buffing towel that helps you removed flashed liquids – and can remove all residue – leaving a perfectly clean surface.

Drying Towels

Just like ceramic coatings, your options for buying a drying towel have been complicated significantly in recent years. There are two general types of drying towels:

Waffle Weave: This is your most common type of drying towel – which also makes it the most outdated. it is usually an 80/20 blend, has a GMS around 500, and displays a unique waffle-shaped pattern. It is cross-stitched to allow the towel to ‘scoop’ water from the surface. The problem is that it tends to be saturated quickly.

Terry Weave: The new kid on the block is the terry weave microfiber drying towel. It is ultra-plush, features a very thick and long pile, and can dry an average sized pick-up in a matter of minutes. The material is usually 70/30, has GMS in the 1,000 to 1,200 range, and usually has a two-sided construction – one for the initial dry, the other for a final ‘detail’ wipe.

Stay tuned to our blog in the upcoming weeks – as we’ll explore some best practices for washing microfiber towels, tips for choosing which microfiber product for specific tasks, and how to pick a cleaning product based on the type of microfiber fabric you choose.